Our packing components enable customers to manage scenarios involving bi-layer and co-packing. They normally contain information that relates to the following.

Preparation Of Batch Packaging Record Bpr Pharmaguideline

The review of batch records creates a story of the.

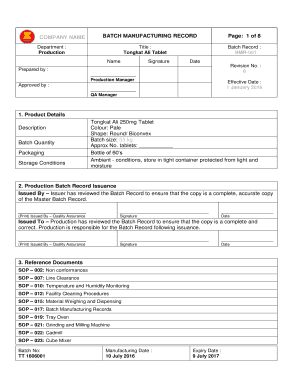

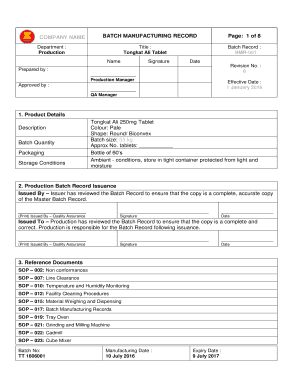

. Batch production and control records shall be prepared for each batch of drug product produced and shall include complete information relating to the production and control of each batch. Batch Packing Records is product and batch specific document designed to give a complete and reliable picture of the packaging history of each batch of every product. Theres more to running a food business than spending all day in the kitchen.

The BR BPR is a. Co-packing for the small producer. A Product name and batch number.

All documents associated with the manufacture of a batch of API bulk product or finished product. Pharmaceutical Technology Pharmaceutical Technology-08-02-2017 Volume 41 Issue 8. A Batch Packaging Record should be kept for each batch or part batch processed.

We specialize in frozen dinners and entrees soups side dishes desserts meal kits and meat components. Batch Manufacturing Records are critical documents for ensuring quality and regulatory requirements are achieved. All contents of the batch record have been checked reviewed found complyingnot complying with the proper requirements.

A Look at Batch Record Review. With packaging capabilities ranging from bulk to retail size and flexible batch sizes we can manage all of your manufacturing and packaging needs. Over printing details Packing details In-process checks Over printing Bottle washing and filling liquid orals Bottle.

It should be based on the relevant parts of the Packaging Instructions. Introduction to the Pharmaceutical E - Batch Packaging Record BPR with Integrated Product Master E-Log with PM Artwork Management System AMS Quality Management System. Batch manufacturing records software specialized for the chemical and process manufacturing industry will automatically convert units of measure and packaging into the base units you.

The batch packaging record should contain the following information. A full-service in-house Quality. 100 BATCH RELEASE.

The batch packaging record should. It should be based on the relevant parts of the Packaging. AmpleLogic Electronic Batch Record Software is a one-of-a-kind software.

Thick and heat-sealed without an easy-open tab dimple corner or flap Types of CRP. BATCH PACKGING RECORDS consists. Date and time of packaging operation.

Batch Record BR or Batch Production Record BPR. As per in process. Single Use Initial CRP the package is initially child-resistant.

A Batch Packaging Record should be kept for each batch or part batch processed. Plastic packaging that is at least 4 mils. What is small batch co-packing.

Content of the Batch Packaging Records BPR BPR shall contain the steps of primary packing as stated in the Master Formula Record with provisions for recording the time of performing the. Fairmont Foods is a highly diversified co-packer with a proven 20-year track record. This document is based on packaging operation.

Its all in the name.

Pharmaceutical Batch Manufacturing Record Sample Download M A N O X B L O G

Preparation Of Batch Packaging Record Bpr Pharmaguideline

Nadlezhashaya Proizvodstvennaya Praktika

Batch Manufacturing Record Excel Template Form Fill Out And Sign Printable Pdf Template Signnow

0 Comments